Rapaport Magazine breaks down the leading options on the market, from physical tracers to user-driven blockchains.

Technology firms have been tackling the challenge of diamond traceability for many years. Now that interest in tracking systems is growing, tech providers are pushing their solutions, which tend to fall into three categories: systems that match the diamond with a digital twin, those that physically mark or analyze the diamond, and those that compile the verified data declarations that users have uploaded about the diamond to a blockchain ledger.

Rapaport Magazine spoke with key players in the diamond-tracing field to understand their respective approaches.

The matchmakers

Diabot

Innovseed’s Diabot machines have scanned over three million diamonds since launching two years ago. The machine sorts the rough production by color, weight, shape and fluorescence, and records a “fingerprint” of each diamond based on those properties. It also takes a 3D model using imaging and video in a completely automated process.

Diabot is a rough-to-rough solution, notes Vipul Sutariya, sales and marketing director of Dharmanandan Diamonds, which oversaw the establishment of Innovseed. Scanning takes place at the mine site and again at the manufacturing stage so a match can be made between the two datasets. It is then the manufacturers’ responsibility to track the diamond through cutting, polishing, grading and sale, using either third-party solutions or their own, explains Sutariya, who also serves as Innovseed’s director.

In May, Innovseed unveiled an updated version of Diabot, improving the scanning speed to 3.7 seconds per stone. The new version can handle all sizes, starting with 10-millimeter melee goods. The company is working with blockchain company Everledger and De Beers’ Tracr program, among others, to empower its solutions. Miner Mountain Province Diamonds, for example, is using Diabot to scan its production for the Tracr program.

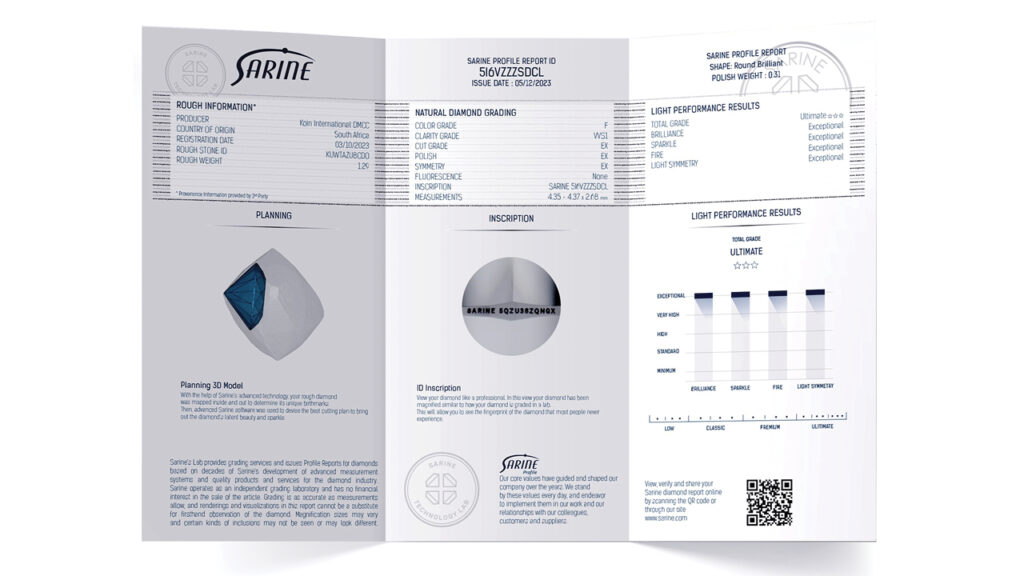

Sarine Technologies

Sarine taps into its network of diamond-planning and manufacturing equipment for its traceability solution.

“We believe traceability means tracking the actual diamond as it flows down the pipeline from the mine to the consumer,” says CEO David Block. “This is possible today due to the extensive use of technology throughout the industry. We can utilize data to prove the diamond started in a particular location and continued its journey throughout the pipeline.”

Under the Sarine system, the rough diamond gets scanned at the mine and again at the manufacturer. The company has partnerships with Tracr and Lucara Diamond Corporation, and is in discussions with other miners to gain access to their rough production. It already has relationships with manufacturers that use Sarine equipment for planning, cutting and polishing purposes.

Sarine takes those scans and compares them, creating a simulation that matches the two datasets. Specific elements such as the diamond’s shape, size, inclusions and fluorescence are part of the equation.

Scanning continues through the various stages of manufacturing, and Sarine gains permission to use the information to maintain the match with the original rough stone.

One result of this is Sarine’s Diamond Journey program, which lets retailers share the story of each stone with the consumer. Jewelers can source goods that carry a Diamond Journey report, ensuring there is a verified trail of ownership all the way through to the retail level. The data from the Diamond Journey program is also compatible with other blockchain platforms, according to Block.

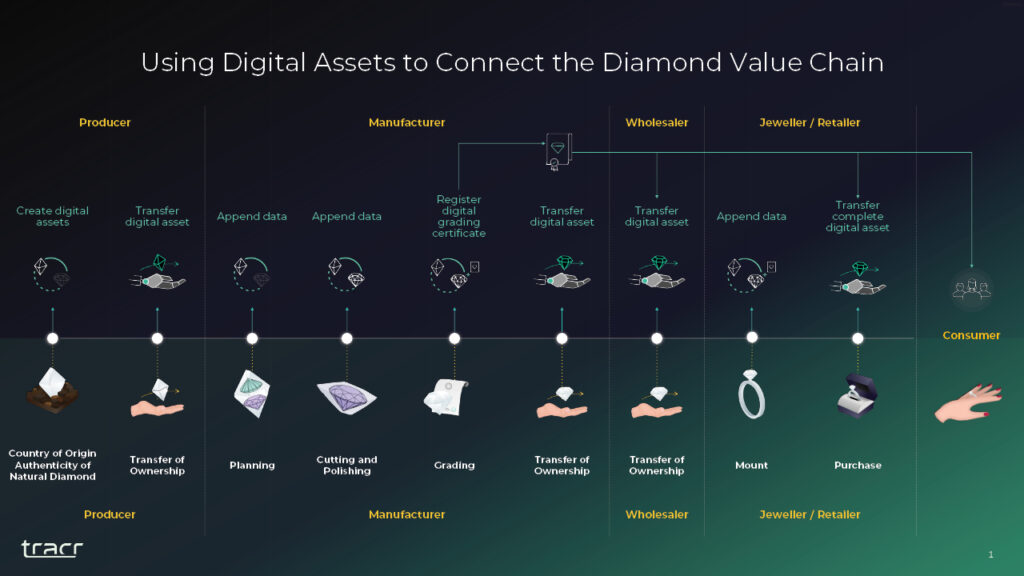

Tracr

Tracr was developed by De Beers, although it is reportedly seeking to function independently as a nonaffiliated industry platform. Still, it has access to the miner’s production, and a strong link to the company’s manufacturing sightholder clients. Tracr also has partnerships with Sarine and the Gemological Institute of America (GIA) that make it compatible with their programs. There are some 2.6 million rough diamonds and 400,000 polished ones on the platform, according to the company.

“Tracr has found the sweet spot for the industry in terms of depth, certainty and scale,” says CEO Wesley Tucker. “I don’t believe traceability can start [just] anywhere, because the burden of proof will never be enough. This macro trend of [showing the] origin, requiring full provenance traceability, is not going away.”

Tracr tracks and measures companies, facilities and physical diamonds, Tucker explains. Participants must comply with De Beers’ Best Practice Principles (BPP) or be members of the Responsible Jewellery Council (RJC).

The producer records the origin when scanning the stone at the mining stage and uploads a “digital twin” to the platform. This creates a record of the diamond’s authenticity and provenance.

The rough gets scanned again at the factory, and an algorithm matches this scan with the one from the mine. As it progresses through manufacturing and then changes hands as a polished diamond, each party adds its transaction data to the blockchain, and third-party audits ensure the segregation and integrity of the goods. Finally, the jeweler gains access to the digital asset showing the diamond’s journey.

Tracr only scans gem-quality rough above 3-grainers. Because De Beers aggregates all of the rough from its operations in Botswana, Canada, Namibia and South Africa, the company declares the source simply as “DTC.” The aggregated rough gets scanned in Botswana, but De Beers also scans the diamonds at its separate partner trading centers — a move that makes it possible to disclose the goods’ individual countries of origin, as Tracr reportedly plans to start doing.

The physical identifiers

Authentia

As early as 2012, Bruno Scarselli submitted flawless and internally flawless diamonds to three different grading labs after marking the stones with nanotechnology for identification. The diamonds came back with the same grades as before, demonstrating that the technology could be applied without affecting the stones’ quality, the diamantaire recalls.

While nanotechnology has long been in use across various industries, its application to diamonds is relatively new. In the decade since his test, Scarselli has developed a blockchain program that uses nano-marking as a basis for diamond traceability.

The resulting platform, Authentia, applies the nano-marker at the rough stage and uploads information about the diamond to the blockchain based on legal documents that attest to its origin. The combination of nano-marking and the blockchain record enables a seamless transfer of data authenticating the diamond’s origin as the rough diamond changes hands.

The digital record follows the diamond through cutting, polishing and the rest of the pipeline. Meanwhile, additional nano-marking occurs at the polished stage, providing an immutable way to identify the diamond through the rest of its journey.

The company will produce its own origin certificates and titles of ownership in order to ensure transparency in the diamond industry, Scarselli stresses. Consumers who buy these diamonds will have access to a detailed and permanent record of the diamond’s history, including its origin, certifications and previous owners.

Authentia is working with some 120 alluvial miners in South Africa, Scarselli reports, and recently signed a memorandum of understanding with the South African Diamond Producers Organization (SADPO) to advance traceability for its members. It did the same with the African Diamond Producers Association (ADPA). Scarselli expects to have some 2.8 million to 3 million carats on the Authentia blockchain by the end of the year.

Gemological Institute of America (GIA)

As a research-based organization, the GIA takes a scientific approach to traceability, explains chief operating officer Pritesh Patel. Under its Diamond Origin program, the GIA assesses the rough diamond and makes the match by analyzing the polished stone when it returns for grading.

Participants in the program — whether miners, tender houses or manufacturers — send rough to GIA labs in sealed parcels along with the stones’ Kimberley Process (KP) certificates. The GIA assesses each rough diamond and assigns it an identifying number, noting where it originated. The lab then sends the rough back to the provider, and the diamond goes through manufacturing.

When the stone comes back to the GIA for grading, the lab does an analysis of the polished diamond based on the GIA’s proprietary methods, confirming that the polished stone came from the rough with the associated ID. It then issues a Diamond Origin Report verifying the stone’s country of origin. Other programs can use that information to support their traceability claims.

The GIA also offers its Source Verification Service, which has third-party auditors validate the processes that manufacturers have in place. The auditors look at variables such as how the company traces the diamond, the information it gathers, and its supply chain documents. Once the company has been vetted, it can submit the stone through the service and let the GIA know the diamond’s origin, Patel explains, since the company now has validation that its claims of source verification are trustworthy.

Opsydia

Born out of Oxford University research, Opsydia inscribes a unique identifier inside each diamond at the polished stage. The identifier verifies the stone and can link with all the information that various traceability companies collect, explains CEO Andrew Rimmer. The inscription cannot be applied at the rough phase, as it would be lost in cutting and polishing, he notes.

The crucial element of nano-scale inscriptions, according to Rimmer, is that the company can put them inside the diamond without affecting its clarity — and they are unremovable.

While Opsydia does not have its own traceability blockchain program, its technology supports others, with the mark providing a physical link between the polished stone and its grading report, blockchain record or branded jewelry origin. The company is in discussions with several traceability providers to integrate its technology into their systems.

“We are technology-agnostic and very happy to integrate with whichever traceability platform the jeweler or manufacturer is using,” Rimmer says. In the near future, Opsydia is planning to launch “viewers” that will enable jewelers to showcase the nano-inscription in the store, verifying the diamond for the consumer.

Provenance Proof

With its origins in colored gemstones, Provenance Proof draws on its groundbreaking work with emeralds. Formerly part of the Gübelin Gem Lab, the group managed to tag rough emerald crystals with a nanoparticle solution, leaving a permanent invisible mark on the stone without affecting

its quality.

Emeralds are distinctive in that they have fractures into which the nanoparticles can be injected, explains Provenance Proof CEO Klemens Link. An independent auditor tags the emeralds with physical tracers at the mine site by “bathing” production in the solution in batches, and the tracers remain intact through the cutting and polishing process.

The same cannot be said for diamonds and other gemstones, however, as they are more compact and lack the fractures characteristic in emeralds. “We were hesitant to offer the solution for diamonds, because we knew it could only start at the cutting facility,” recalls Link. “But we soon recognized that offering physical traceability throughout the remaining supply chain is already much more than there is elsewhere on the market.”

Using the same nanoparticle solution it applies to emeralds, Provenance Proof gives jewelers a secure, physical way to trace a polished diamond back to the cutting facility. The company has also expanded its emerald blockchain system to track the marked diamonds. One can enter the rough diamond into the blockchain at the mine and link it to declarations further down the pipeline, Link says, and it easily connects to other blockchain programs.

“Interoperability of the different digital traceability solutions is one of the key things for the industry,” he states.

The digital compilers

Diatrace

Vinit Jogani takes a holistic view when addressing diamond-tracking.

“We have to ask why we’re doing traceability,” says the director of Diatech, which developed the Diatrace system. “If the goal is to show the diamond is ethical, ethics go far beyond just saying origin.”

Diatrace encompasses environmental, social and governance (ESG) components in its approach to ethical standards, Jogani explains.

The company has built processes that guide the user in uploading diamond and jewelry data to its blockchain platform. It uses artificial intelligence (AI) to recognize each diamond’s specific characteristics and create an immutable digital record of the stone on the blockchain. The record serves as the diamond’s digital passport, containing its origin and validating its authenticity throughout the supply chain, the company explains.

Data can be uploaded at any point in the diamond’s journey, and the information gets transferred across transactions between stages, Jogani adds.

Diatrace backs up this process via audits, assessing a diamond company’s sustainability and ESG credentials. The audits focus on that company’s environmental footprint, social issues pertaining to the work environment, corporate social responsibility (CSR) practices, and governance.

“We need to take a step back from the industry’s short-term needs, which emphasize the origin story, and realize what’s really important,” Jogani says. “The long-term requirement is to preserve the natural diamond brand, which is built on values and trust.”

The current sanctions on Russian diamonds may or may not motivate companies to adopt traceability measures, but they’ll likely be more willing to consider it if you tell them that doing so will help demonstrate their ethics, he argues.

Everledger

As an industry outsider, Everledger considers itself a pioneer that “painfully introduced the awakening that traceability is inevitable,” says founder and CEO Leanne Kemp.

That said, she cautions that complete, 100% scientifically proven, full-chain-of-custody traceability isn’t necessarily achievable with current technologies or a single technology. “It’s crucial to acknowledge the inherent challenges and limitations in the process,” Kemp says. “Perfect traceability remains an aspiration rather than a reality in many cases.”

Everledger’s aim is to provide the best possible information given these constraints, while being transparent about the level of certainty in its traceability claims, she states.

Everledger’s blockchain solution, which launched in 2015, creates an immutable digital ledger that encompasses AI, machine learning, verified credentials, tokenization, blockchain, and the internet of things, Kemp explains.

The company taps several technology providers to upload data about diamonds throughout the value chain. Its approach to matching rough with rough — at the mine and the manufacturer — utilizes the available digital representations of the diamond. For rough-to-polished matching, it can link to other providers’ tracing technology, and for polished-to-polished, the Everledger system holds the digital “fingerprint” that manufacturers’ machines have created for the polished diamonds at their facilities, and makes it available for comparison and analysis.

The platform also has a chain-of-custody system that tracks the flow of diamonds through the supply chain by transaction. That includes data such as mining records, KP certificates, import-export documents, and sales invoices.

“Our system makes it easy to verify origin, trace the journey, and record ethical standards alongside measured environmental impacts,” Kemp explains. “This encompasses value exchange, storytelling, and compliance, as well as fostering a new era of trust and sustainability in global trade.”

iTraceiT

Frederik Degryse draws on his diverse experience within the industry to steer the iTraceiT platform.

“Our approach has always been to acknowledge that the diamond supply chain is intricate, with many different types of companies that operate in varying circumstances,” says the iTraceiT CEO.

The challenge is to map out the diamond at every stage, not just at the mine or the manufacturer, he explains — getting everybody involved and applying it to all diamonds. That includes melee, which many solutions avoid.

The iTraceiT system uses QR codes to access specific information about the diamond on the blockchain. The data collection typically begins at the rough stage, with participating miners or manufacturers uploading details such as the mine name, the KP certificate, and other related documents. Parties can attach additional data and documents at any point along the supply chain, all the way through to the retailer. The user scans the QR code to view these supporting documents, and the company has added an option to provide third-party legal verification that the information is correct.

The platform includes declarations about melee goods, which typically come in mixed parcels consisting of stones from various sources. ITraceiT requires suppliers to declare, “to the best of their knowledge,” the percentage of goods from each source, whether named or unnamed. For the latter, they must disclose the goods as “origin unknown.”

The iTraceiT solution can connect to any system or blockchain, Degryse states. That means if a diamond starts its traceability journey at the mine on another platform but passes on to a manufacturer that uses iTraceiT, the data can transfer with it. The same is true if the stone then sells to a retailer that uses a different blockchain.

“We can be the glue between solutions,” Degryse declares. “Whether the information is pushed on the iTraceiT blockchain or another platform is not so important for us.”

Main image: Illustrative image of a diamond. (David Polak/Midjourney)